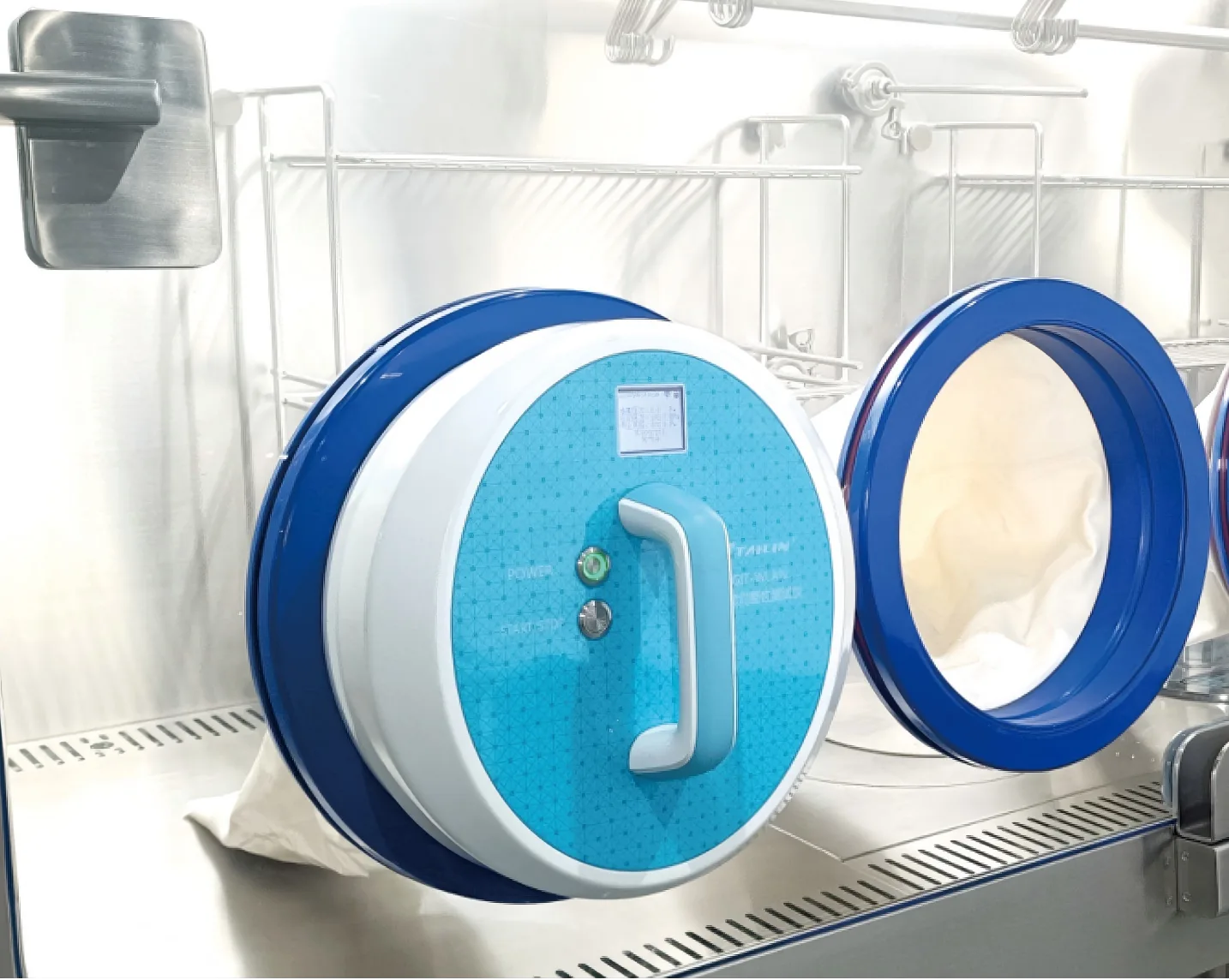

Home > Leak Test System > Glove Integrity Tester (GIT) > Glove Integrity Tester

The GIT-WLAN02 is used to leak test gloves installed on isolators or RABS. It performs the pressure decay test automatically and stores all data and results wirelessly on a PC with database support. It meets the requirements of ISO 14644-7 Annex E.5. and EU GMP Annex 1.

| Inflation Pressure: 500~2500Pa | Test Time: 3min~6min |

| Pressure Display Resolution: 0.1Pa | Smallest Detectable Hole: 100μm |

| N.W.: ≈3kg | Dimensions: Ф280mm×150mm |

| Battery: 12V Lithium battery | Power: ≤20W |

| Continuous Working Time: ≥4 hours | Communication: WIFI |

ISO14644-7 Annex E.5

“The pressure decay tests described are only a few of many tests that can be used for glove testing and are intended to illustrate glove leak test procedures.”

EU GMP Annex 1 (2022) 4.21

“For isolators, leak testing of the glove system should be performed using a methodology demonstrated to be suitable for the task and criticality. The testing should be performed at defined intervals. ”

“For RABS… Gloves should be visually examined with each use, and integrity testing should be performed at periodic intervals.”

FDA Guidance for Industry: Sterile Drug Products Produced by Aseptic Processing (2004) Appendix 1

“…Physical integrity tests should also be performed routinely. A breach in glove integrity can be of serious consequence. …”

Yes. For gloves in different areas, the GIT-WLAN02 can be wired over a network for group control. Test results from each area are transmitted over the wireless network for server-side file sharing, centralized monitoring, and streamlined data management across multiple isolators or RABS zones.

Yes. The GIT-WLAN02 is compatible with all standard glove types, including CSM, EPDM, and Nitrile, as well as custom flange configurations. Its ultra-fast inflation and airtight connection system ensure consistent, repeatable results across glove materials.

The tester performs fully automatic monitoring of glove and flange pressure variations during testing. Real-time data is displayed on the user interface and transmitted wirelessly to the monitoring system for centralized storage and analysis. Monitoring system supports multi-level permission groups.

Yes. The GIT-WLAN02 software meets 21 CFR Part 11 requirements for electronic records and e-signatures, includes multi-level user authority groups, and enforces a secure data review process. All test results are automatically logged and traceable for audit and validation purposes.

The GIT-WLAN02 supports both wired and wireless communication, allowing unlimited glove testers to be monitored simultaneously from a central platform.

It also supports OPC UA and Modbus protocols for seamless integration with SCADA, MES, and other automation systems, enabling unified data management and interoperability within modern pharmaceutical production environments.

An optional cleanroom tablet PC is available for on-site operation and visualization.