Home > Applications > Pharma

Pharma

Pharma machinery solutions support the full spectrum of aseptic pharmaceutical manufacturing, from pharma processing, precise filling to safe transfer and quality control. Designed around advanced isolation technology, they create controlled, contamination-free environments that protect both operators and products. Fully GMP-compliant, these systems ensure reliability and safety in applications such as injectables, vaccines, and high-potency compounds, playing an important role in driving the advancement of Pharma 4.0.

Pharma Isolator

Function and Purpose

A pharmaceutical isolator is a fully enclosed, gas-tight, and sterile system that provides a physical barrier to ensure contamination control and operator protection.

Depending on process requirements, isolators can operate under:

- Positive pressure for product protection

- Negative pressure for product & operator safety

They are essential for aseptic compounding, fill-finish operations, and handling of potent compounds.

Tailin Isolator Portfolio

Tailin provides customized isolation systems that comply with GMP, USP, and EP standards, including:

- Sterility Test Isolators

- Aseptic Filling Isolators

- Containment Isolators for APIs and HPAPIs

These systems effectively reduce contamination risks and ensure consistent, reliable performance in drug production.

More

Pharmaceutical Dispensing

Precision and Automation

Tailin High-Precision Pharmaceutical Dispensing Solutions enable automated aseptic filling, capping, and stopper operations for R&D, trial and pilot-scale production.

They ensure GMP compliance, and deliver precise, zero-waste performance to accelerate lab-to-clinic development.

More

Sterile Transfer

Safe and Contamination-

Free Transfer

Sterile Transfer ensures materials or products move safely between cleanrooms or controlled environments. It maintains aseptic conditions, prevents cross-contamination, and ensures compliance with GMP standards in pharmaceutical operations.

More

Integrity Testing

Glove Integrity Testing

In aseptic production, isolators and RABS systems require regular integrity verification to maintain sterility.

For isolators, leak testing of the glove system should be performed using a methodology demonstrated to be suitable for the task and criticality.

For RABS, gloves should be visually examined with each use, and integrity testing should be performed at periodic intervals.

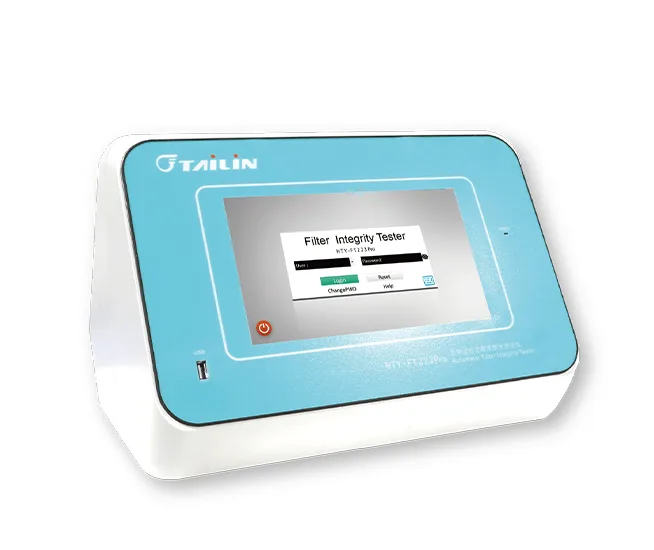

Filter Integrity Testing

Sterilizing-grade filters are essential barriers ensuring product sterility. Integrity testing verifies

filter performance, confirming compliance with global GMP requirements.

Tailin Filter Integrity Testers offer multiple standard functions:

Forward Flow Test

Bubble Point Test

Water Intrusion Test

Combined Forward Flow and Bubble Point Test

Pressure Hold Test

Container Closure Integrity Testing (CCIT)

Container closure integrity (CCI) refers to the ability of a pharmaceutical packaging system to prevent product loss, microbial ingress, and the entry of other gases. For sterile products, a robust packaging system is essential to ensure product safety and quality.

Typical testing methods include:

- Vacuum/Pressure Decay

- High-Voltage Leak Detection

- Headspace Analysis

- Microbial Challenge Testing